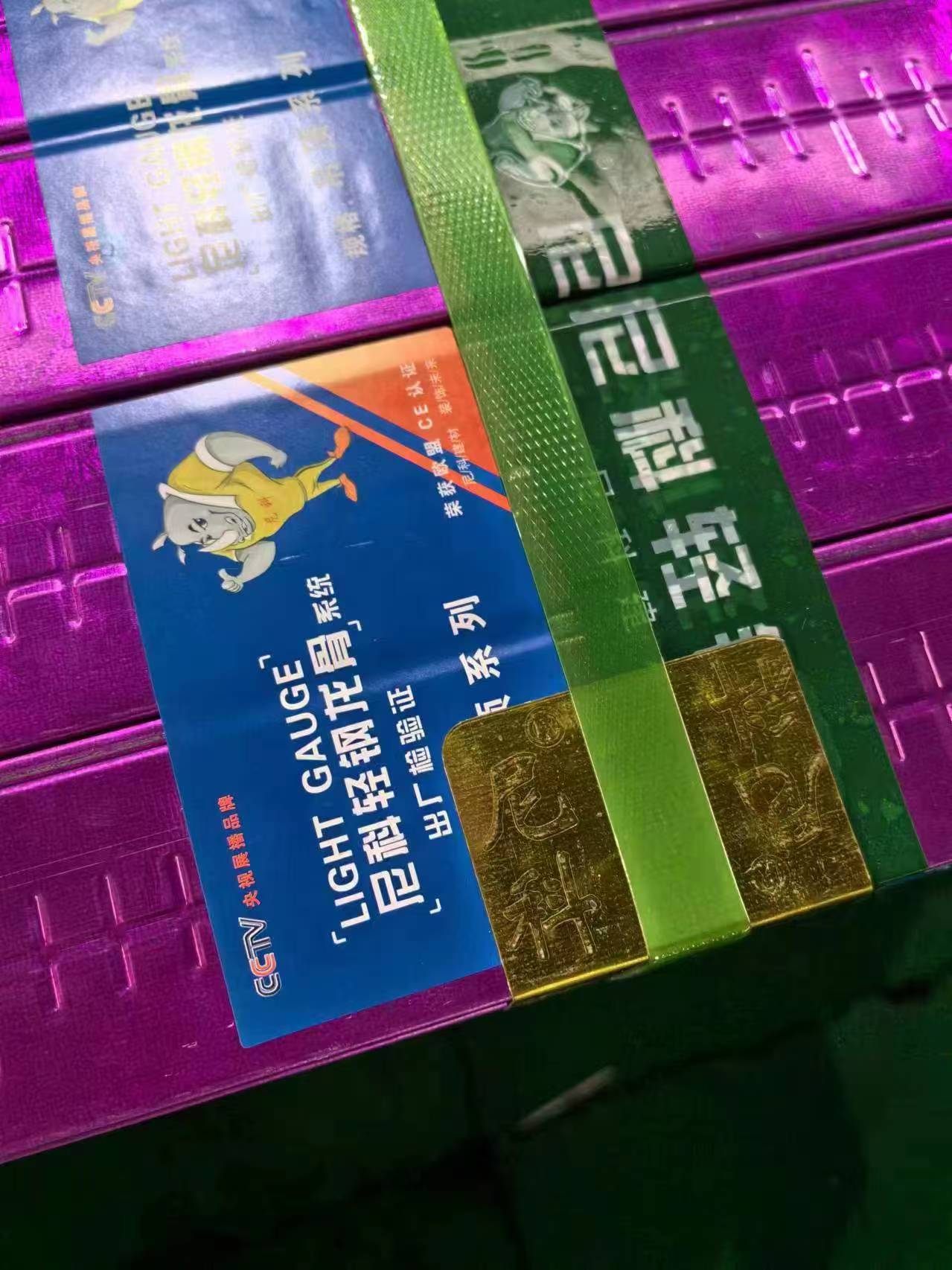

Light Steel Keel Series

Light steel keel

- Product Series:Light Steel Keel Series

- QQ:

- Phone: 0086 13421388033

- WhatsApp: 0086 13421388033

- Email: ms.li@hbgtjc.asia

- FEEDBACK

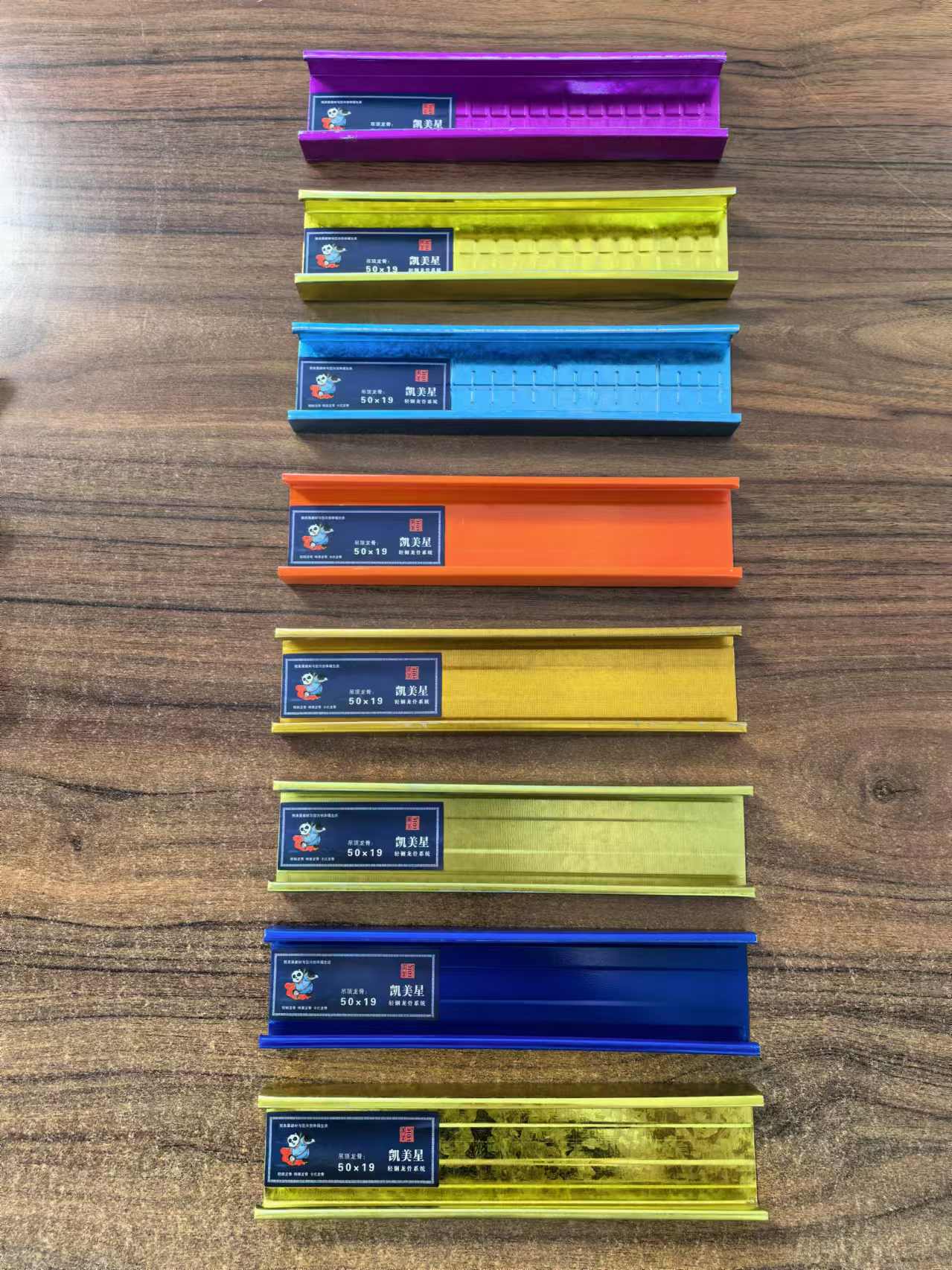

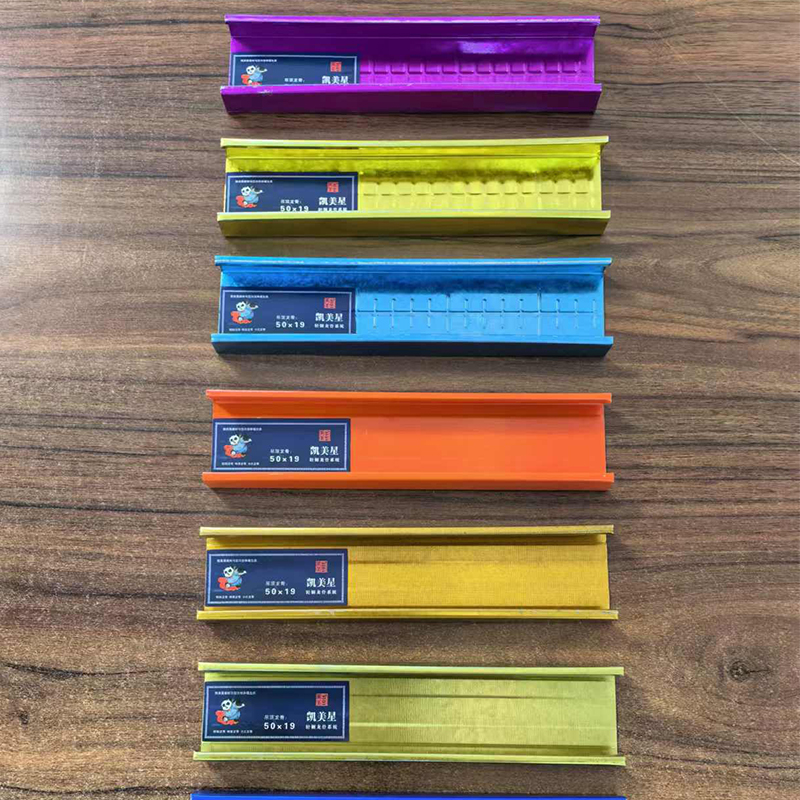

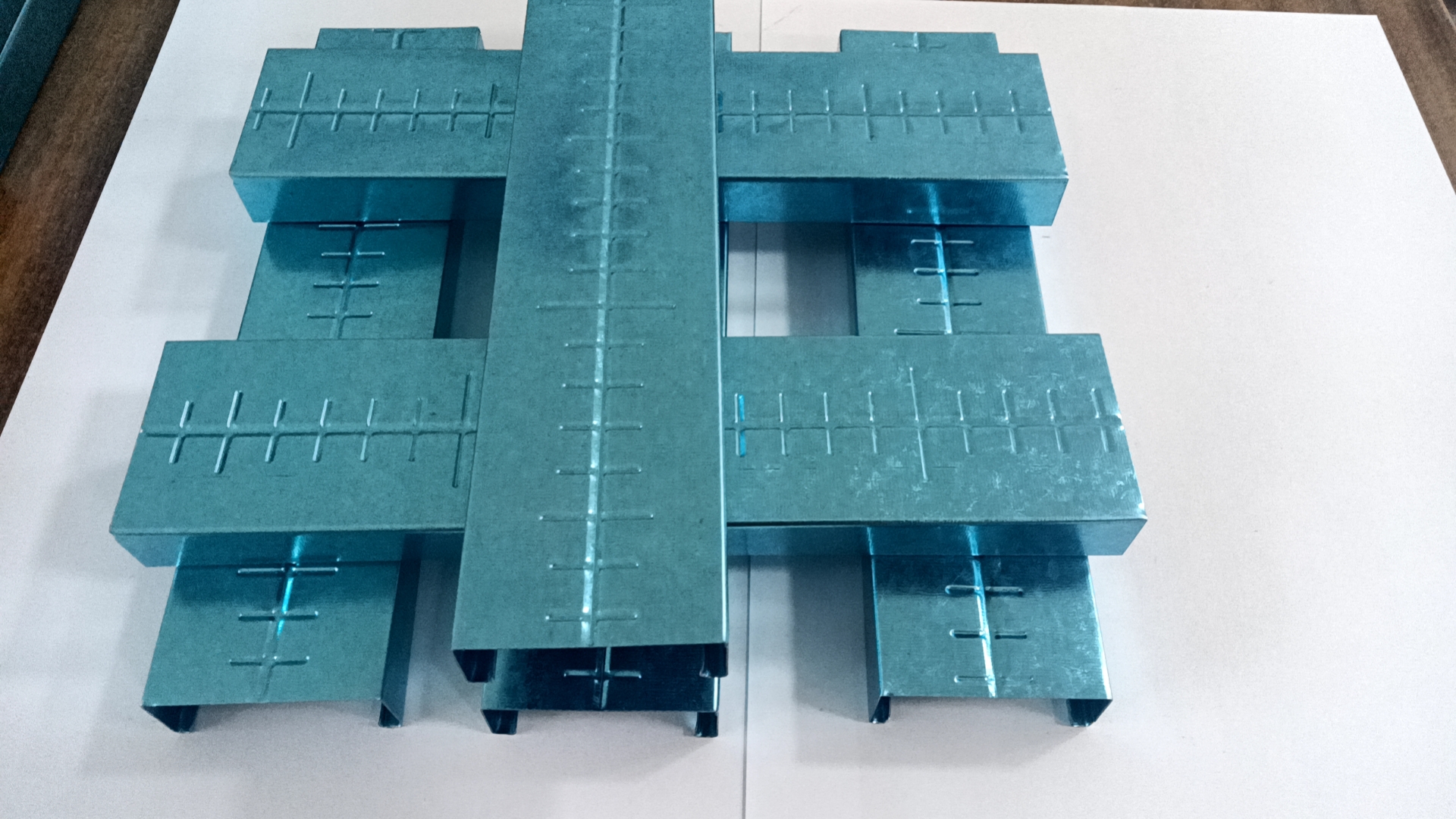

Types of light steel keels:

Light steel keels are classified into ceiling keels and partition keels according to their uses, and V-shaped, C-shaped,

T-shaped, L-shaped, and U-shaped keels according to their cross-sectional forms.

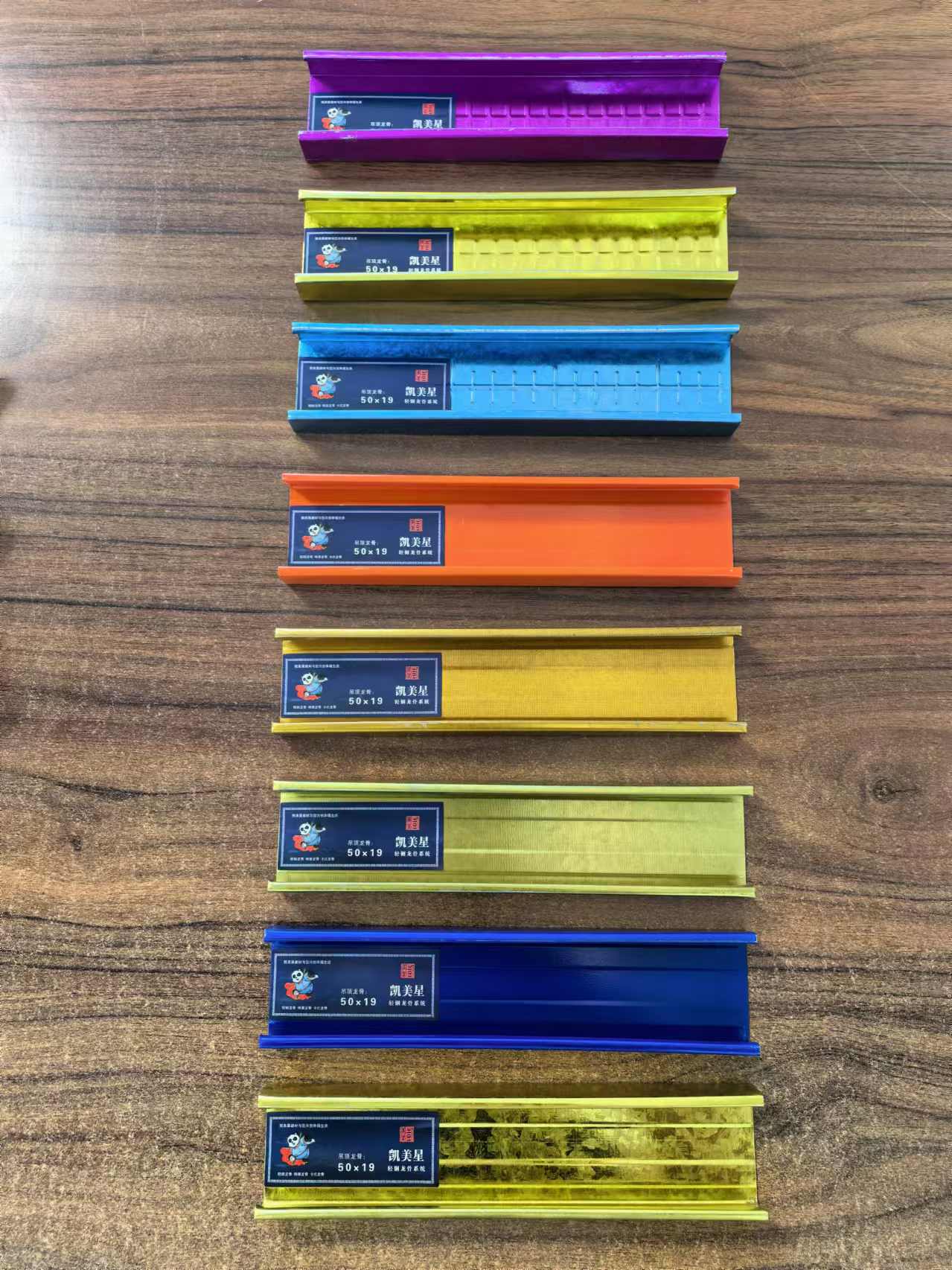

The marking order of light steel keels is: product name, code, width of cross-sectional shape, height, steel plate thickness,

and standard number. For example, a ceiling keel with a cross-sectional shape of "C", a width of 50mm, a height of 15mm,

and a steel plate thickness of 1.5mm is marked as: Light steel keel for construction DC50×15×1.5 GB11981.

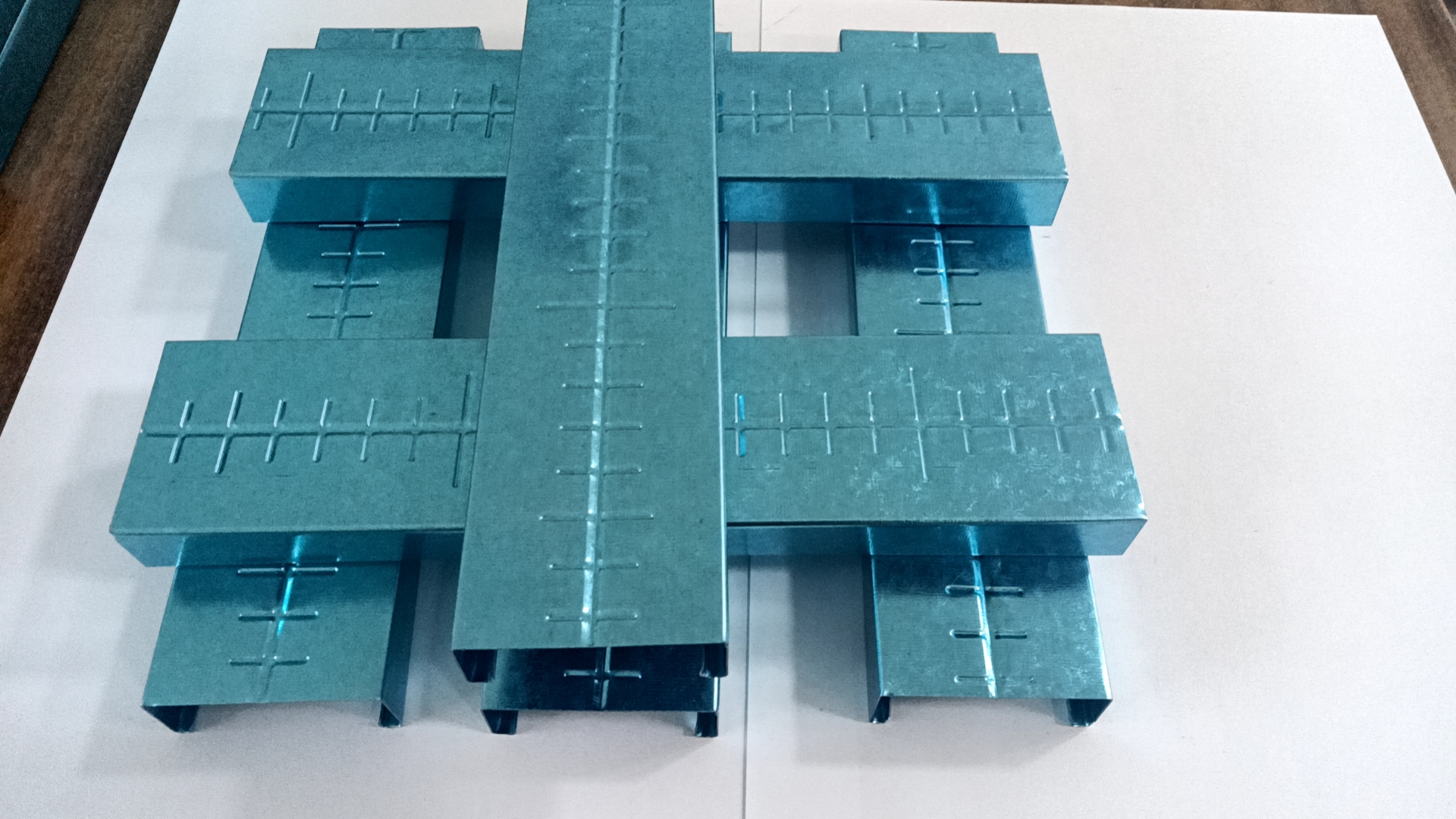

Appearance quality The appearance of light steel keels should be flat, with clear edges and corners, and the cuts should not

have burrs and deformations that affect use. The galvanized layer is not allowed to have defects such as peeling, tumors,

and shedding. For defects such as corrosion, damage, black spots, and pitting, the specified method should comply with

the provisions of Table 2-81 when tested. When inspecting the appearance quality, visual inspection should be carried

out under bright light conditions at a distance of 0.5m from the product.

The surface of the light steel keel should be galvanized for rust prevention, and the double-sided galvanizing amount: the

superior product is not less than 120g/m*m

Advantages of light steel keel:

1.Light weight: The texture of the light steel keel is relatively light. If a 9mm gypsum board is used to assemble and ceiling,

it is one-fourth the weight of the plastered ceiling.

2.Excellent fire resistance: Therefore, the light steel keel is usually a partition composed of 2 to 4 layers of gypsum boards, so

its fire resistance is very good, reaching 1.O~1.6h, so the fire resistance of the light steel keel is very good.

3.High construction efficiency: Because the texture of the light steel keel is relatively light, it can be constructed by assembly

method, and the construction is also relatively fast. Generally, professional construction personnel can complete the partition

of 3 to 4 meters in one day.

4.Safe and reliable structure: The light steel keel also has the characteristics of high strength and high rigidity, so the ceiling

made of it is very safe and reliable.

5.Good impact resistance: If the light steel keel is combined with a 9 to 18 mm thick gypsum board partition, its breaking load

value can reach 390N to 850N, so it has good impact resistance.

6.Good earthquake resistance: The light steel keel and the surface layer are generally fixed with sliding connectors such as nails

and screws, so it has good earthquake resistance. For example, during an earthquake, the partition will only slide, which will not

affect the light keel and the surface layer, nor will it be damaged.

7.Improve heat insulation, sound insulation and indoor utilization: Because the light steel keel partition occupies a relatively

small area, but its insulation performance is better than a brick-thick wall. For example, if other insulation materials are added

to the light steel keel, its insulation effect is like a 37 mm thick brick wall. It is generally used for partitions in entertainment

venues and offices, which can not only effectively insulate but also improve indoor utilization.

Disadvantages of light steel keels:

Light steel keels must be combined with main keels, covering keels and fasteners during construction, so they need to

occupy a relatively large area and be at least 10 cm to 15 cm in height. Moreover, light steel keels can only be made into

straight lines and cannot be made into other special shapes.

CATEGORIES

LATEST NEWS

CONTACT US

QQ:

Phone: 0086 13421388033

WhatsApp: 0086 13421388033

Email: ms.li@hbgtjc.asia

Add: Fanzhuang, Jinzhou Town, Jinzhou City, Shijiazhuang City, Hebei Province, China